Spring

Product Description

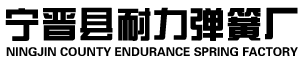

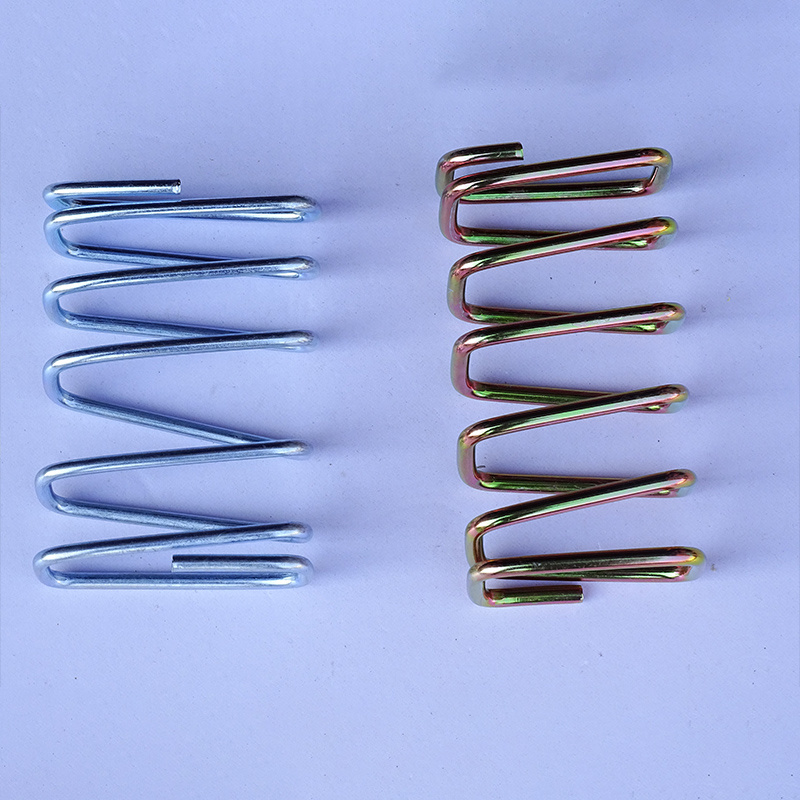

According to the nature of the force, springs can be divided into tension springs, compression springs, torsion springs, and bending springs. According to their shape, they can be classified as disc springs, ring springs, leaf springs, helical springs, conical coil springs, and torsion bar springs, among others. Based on the manufacturing process, they can be divided into cold-wound springs and hot-wound springs. Ordinary cylindrical springs are widely used due to their simple manufacturing process and the ability to produce various types based on load conditions, as well as their simple structure. The materials used for manufacturing springs generally should have high elastic limits, fatigue limits, impact toughness, and good heat treatment properties. Common materials include carbon spring steel, alloy spring steel, stainless spring steel, as well as copper alloys, nickel alloys, and rubber. The manufacturing methods for springs include cold winding and hot winding. Springs with a wire diameter of less than 8 millimeters are generally made using the cold winding method, while those greater than 8 millimeters use the hot winding method. Some springs may also undergo shot peening or shot blasting after production to enhance their load-bearing capacity.

Key words:

Related Products

Get Free Product Quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:+8613473081830/+8615003197767

0086-319-5683588

0086-319-5683588 1037904363@qq.com

1037904363@qq.com

Faedback

Faedback